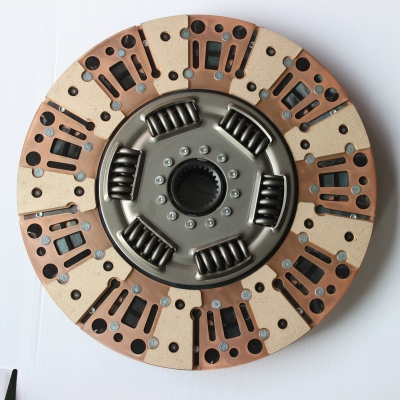

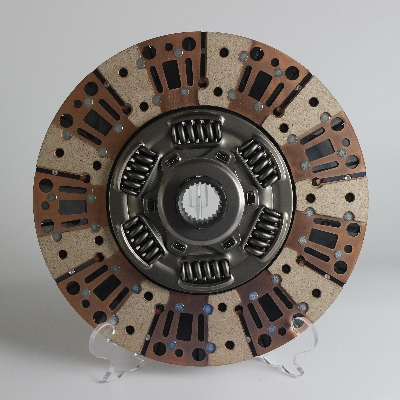

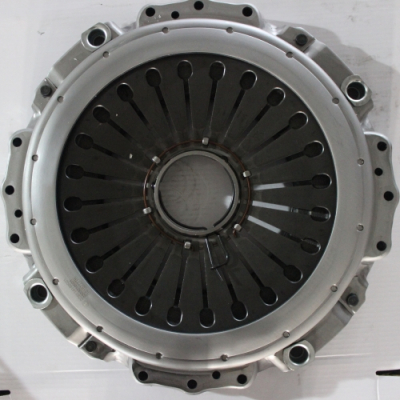

Mining Clutch Disc

Features:

1. Torque Capacity: The clutch disc's torque capacity should be able to handle the engine's power output. Higher torque capacity is required for high-performance vehicles with more powerful engines.

2. Reliability and Durability: The clutch disc should be designed to withstand repeated engagement and disengagement without excessive wear or degradation. It should have a long service life and be resistant to heat, slipping, and deformation.

3. OEM or Aftermarket: Clutch discs are available as original equipment manufacturer (OEM) replacements or aftermarket upgrades. OEM discs are specifically designed for the car's make and model, ensuring proper fitment and performance. Aftermarket options may offer enhanced performance characteristics or specialized options.

Product description

The clutch disc is an important part of the clutch. It is a circular metal disc, usually made of friction material, mounted on the crankshaft of the engine. The role of the clutch plate is to transmit engine power to the transmission.

When the clutch pedal is released, the friction between the clutch plate and the clutch drive plate will cause them to come into close contact and rotate together. In this way, the engine power will be transmitted to the transmission through the driven plate, driving the vehicle forward.

And when the clutch pedal is stepped on, the friction force between the clutch driven disc and the clutch driving disc will reduce or disappear, so that it will be separated. In this way, the separation between the engine and the transmission can be realized, and the power is no longer transmitted, and the vehicle can be stopped or shifted.

Product parameters

Product Properties | |||

OE NO. | 1601210-76A, 1601210-76B | Product Name | Clutch Disc |

Warranty | 12 MONTHS | Quality | High-Quality/100% Brand new and High quality |

Place of Origin | Shandong,CHINA | Packing | Carton/ Neutral Packing |

Supply Ability | 1000 Set/Sets per Month | MOQ | 10pcs |

Size | 430MM/OEM Standard | Weight | 15 kg |

Type | Clutch Disc/Clutch Assembly | Payment | T/T |

Brand Name | LH | Material | Iron and copper |

Condition | New | Delivery time | 7-15days |

Color | As shown | Shipping | DHL UPS EMS FEDEX |

Port | Qingdao port | Certification | TS16949 |

Truck Model | XCMG,LCMG,SDLG,SANY,LiuGong, TONLY,CNHTC | ||

The process of making a clutch disc

1. Material selection: The first step is to select the appropriate materials for the clutch disc. Typically, clutch discs are made from a combination of metal and friction materials, such as steel or iron for the disc base and friction materials such as organic or ceramic materials for the friction surface.

2. Cutting and stamping: The flat metal discs are cut from the selected metal material to the desired size and shape using cutting and stamping processes. This involves using specialized machinery and tools to achieve precise dimensions.

3. Heat treatment: The metal discs are then subjected to heat treatment processes to improve their mechanical properties, such as strength and durability. This may include processes like annealing, quenching, and tempering to achieve the desired hardness and toughness.

4. Friction material application: The friction material, usually in the form of thin layers or liners, is then applied to the surface of the metal discs. This can be done through processes like bonding, riveting, or being molded directly onto the metal discs. The type and thickness of the friction material may vary depending on the specific application and performance requirements.

5. Balancing: To ensure smooth operation and minimize vibration, the clutch disc needs to be balanced. This involves adding or removing small amounts of material to achieve proper weight distribution and eliminate any rotational imbalance.

6. Quality control: Throughout the manufacturing process, strict quality control measures are taken to ensure the clutch discs meet the required specifications and performance standards. This includes inspections, measurements, and tests to check dimensions, surface integrity, and friction properties.

7. Packaging and delivery: Once the clutch discs pass the quality control checks, they are packaged and prepared for shipment to the customers or assembly lines. Proper packaging is necessary to protect the clutch discs during transportation and storage.

Packaging and shipping

Our Service

1. OEM Manufacturing welcome: Product, Package...

2. Sample order

3. We will reply you for your inquiry in 24 hours.

4. After sending, we will track the products for you once every two days, until you get the products. When you got the

goods, test them, and give me a feedback.If you have any questions about the problem, contact with us, we will offer

the solve way for you.